North Norfolk Railway Diesel Gala 14th-16th June 2013

Mid Norfolk Railway Pictures (all taken by Andy Marrison)

'25 Years in Preservation' Celebration - Mid Norfolk Railway - 10th October 2015

Commemorating members Brian Lockey and Gerald Lambert - Mid Norfolk Railway - 20th August 2016

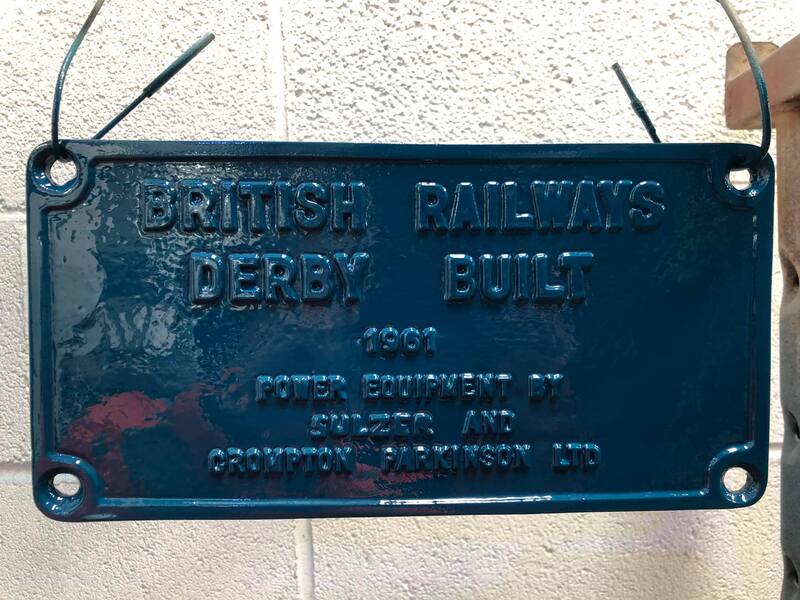

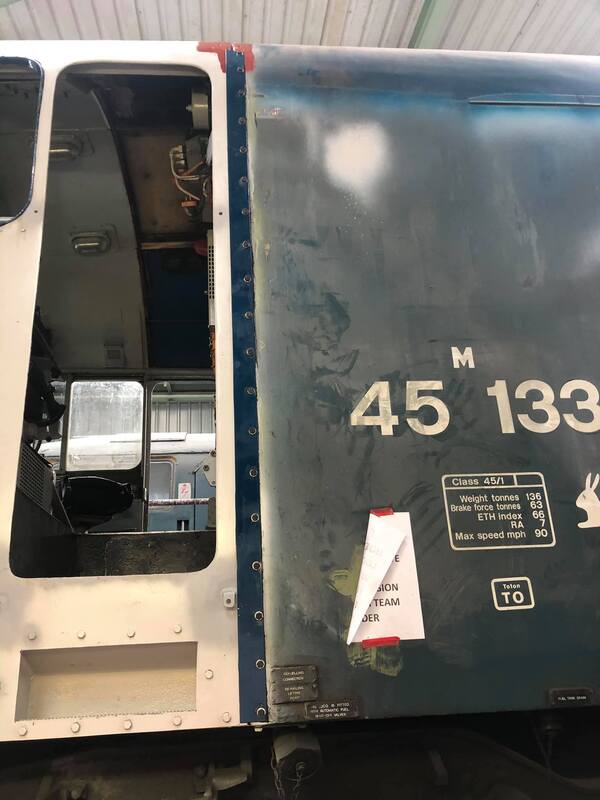

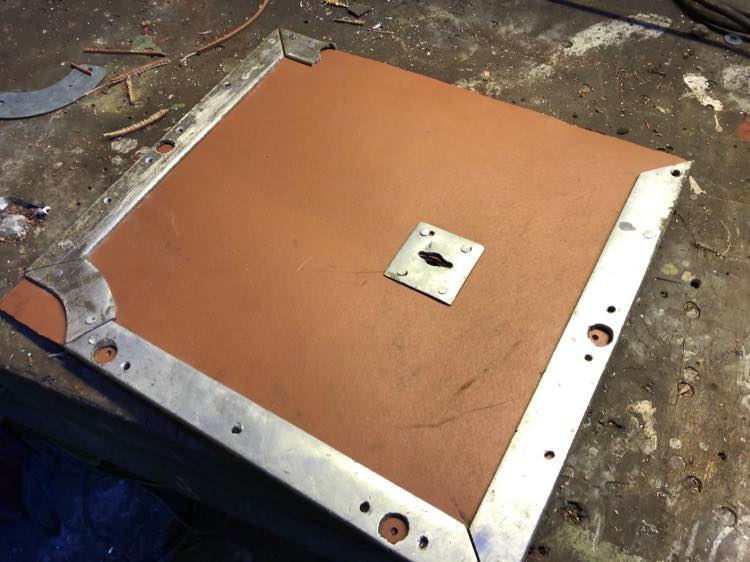

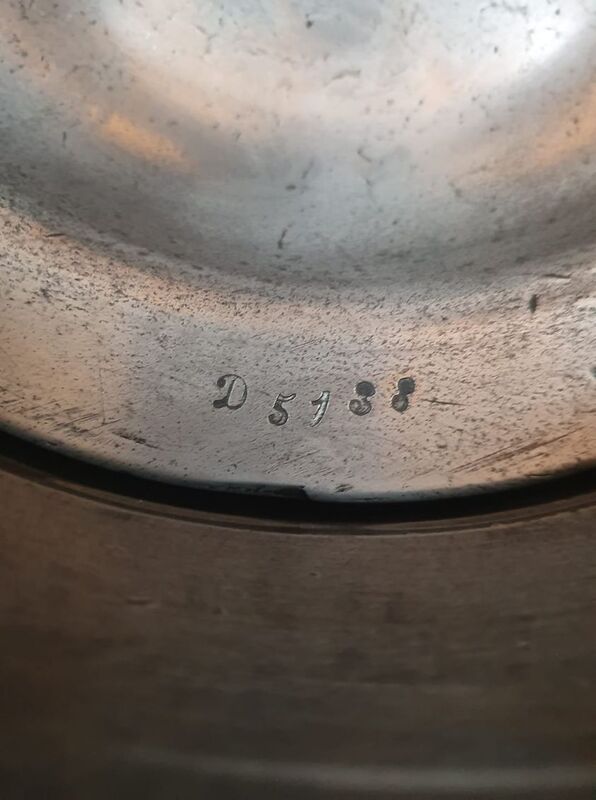

Mid Norfolk Railway Diesel Gala - 30th/31st December 2016 - 45133 breaks new ground.